Purpose:

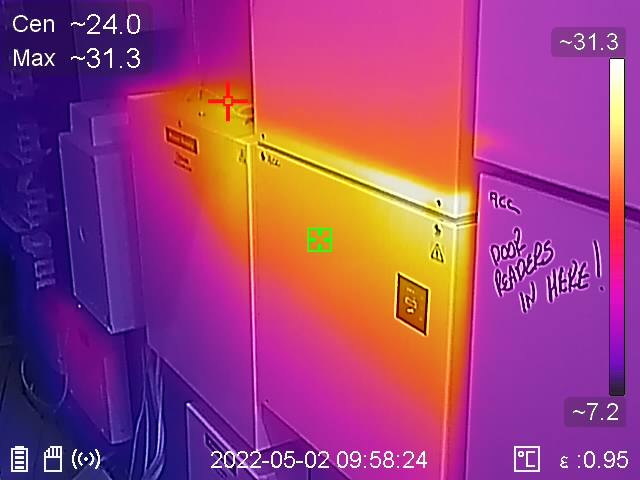

Clearwater were requested by a client to carry out an in-depth thermal imaging survey report within their office premises to look at various fixtures, fittings, and electrical distribution equipment.

Infrared Thermography is an integral part of any Preventive/Predictive Maintenance, Loss Prevention, and Risk Engineering Program. Utilising infrared thermographic scanning on an annual basis for electrical and mechanical systems can improve the reliability of these systems and increase profitability.

Background:

All objects emit electromagnetic radiation of a wavelength dependent on the object’s temperature. The frequency of the radiation is inversely proportional to the temperature. In

In infrared Thermography, this radiation is detected and measured by an infrared detector. The radiation is converted into electrical signals that can be displayed on a monitor. Permanent pictures (thermograms) of the thermal image as seen on the monitor are saved to a compact flash disc. Using internal or external reference temperatures, the operator can calculate the temperature of the object being scanned. The thermal sensitivity of the state-of-the-art detectors used by Global Risk Consultants is 0.04°C at 30°C. Objects of an extremely wide range of temperatures can be scanned, as the state-of-the-art equipment features a temperature range from -40°C to +2000°C.

Infrared Thermography is an integral part of any Preventive/Predictive Maintenance, Loss Prevention, and Risk Engineering Program. Some of the advantages of infrared scanning are:

- Abnormal thermal loading within operating/energised equipment may otherwise be unknown until a point of failure, without utilisation of this technology. Thermographic imaging can help to identify and predict such failures so maintenance efforts can be executed prior to failure.

- GRC’s state-of-the-art infrared thermal imaging equipment utilised maintains precision accuracy (0.1 degree Celsius).

- Discrete temperature measurements are provided to aid in determining the criticality of problems.

- Measurements do not require contact with the object and can be made with the object under full load.

- Infrared thermographic scanning is relatively quick; large footprint areas can be scanned quickly because of the microsecond response of the technology and equipment utilised.

- Safety; use of infrared thermal imaging equipment means measurements are generally made from a safe distance away from objects such as high voltage equipment, equipment at high temperatures, or equipment in a corrosive environment. However, the Thermographic Consultant still remains donned in the appropriate Personal Protective Equipment (PPE) required by internationally recognised standards.